Why Aluminium Angle Sizes Matter: Strength, Versatility and Design Flexibility

When it comes to aluminium profiles, few products are as widely used as aluminium angles. Available in a range of aluminium angle sizes, they are prized for their strength-to-weight ratio, versatility, and design adaptability. Whether you’re working on architectural interiors, structural frameworks, or bespoke fabrication projects, understanding the role of angle sizes is key to achieving the right balance of durability, aesthetics and performance.

At Gooding Aluminium, we supply a comprehensive range of equal angle aluminium and unequal angle aluminium profiles, making it easier for designers, builders and fabricators to select the right fit for their projects.

The Importance of Aluminium Angle Sizes

Aluminium angles are structural components shaped into an ‘L’ profile. The size of each leg determines not just its appearance, but also how much load it can bear and where it can be applied.

- Strength and Stability: Larger aluminium sections can provide additional rigidity, making them suitable for load-bearing structures.

- Lightweight Construction: Even at bigger dimensions, aluminium remains lightweight, which simplifies handling, transport and installation compared to steel.

- Design Flexibility: From small detailing to large-scale frameworks, a variety of aluminium extrusions ensures there’s an angle size for every project.

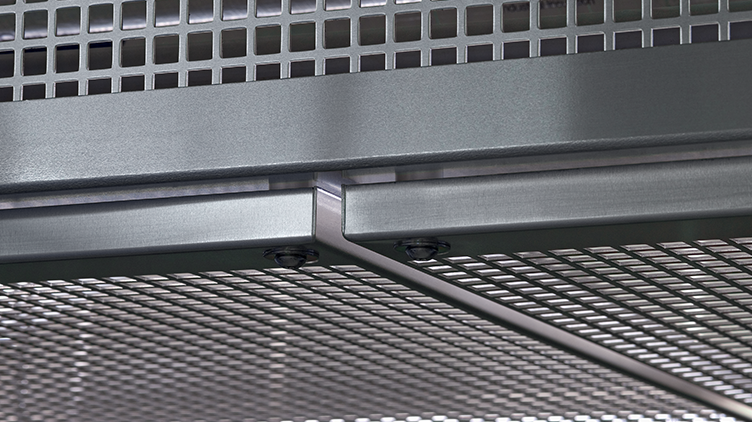

Equal vs Unequal Aluminium Angles

Equal Angle Aluminium

Equal leg sizes create a balanced profile. These are commonly used for:

- Framing and brackets

- Edge protection

- Corner reinforcement

They provide symmetrical strength, making them reliable in both architectural and structural applications.

Unequal Angle Aluminium

With one leg longer than the other, unequal angle aluminium offers:

- Greater flexibility in design

- Enhanced load-bearing in one direction

- Ideal for custom fabrications where non-standard proportions are required

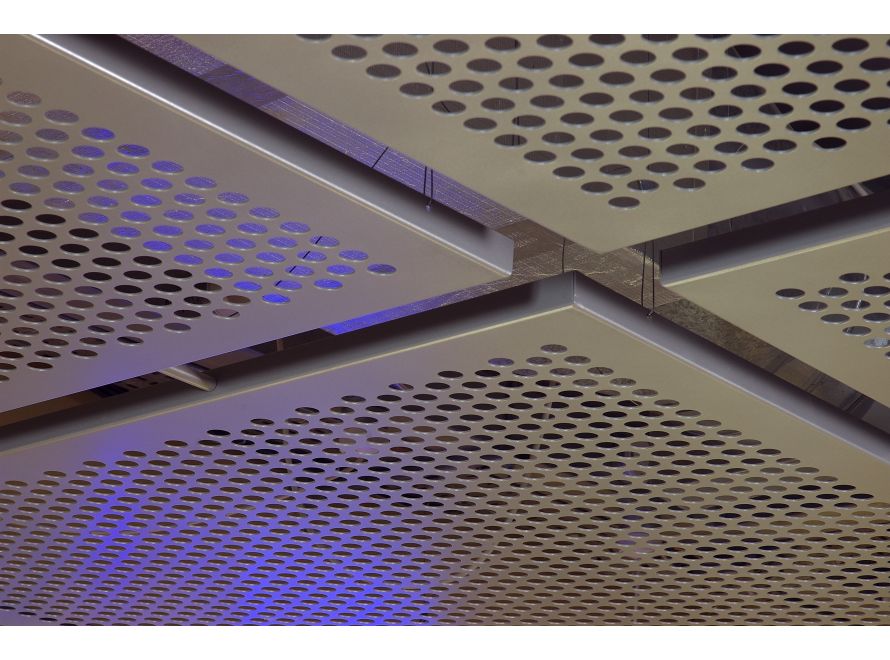

This variation is often used in architectural aluminium projects where visual detailing is as important as structural integrity.

Applications of Different Aluminium Angle Sizes

Depending on the chosen profile, aluminium angles are used across many industries in the UK:

- Construction: Structural support, window framing, partitioning

- Architecture & Interiors: Decorative trims, furniture, corner protection

- Retail & Hospitality: Display stands, shelving units, fixtures

- Transport & Engineering: Lightweight framework, reinforcement brackets

- Custom Fabrications: Bespoke solutions for unique design challenges

These applications highlight why durable aluminium is such a sought-after material.

Benefits of Choosing the Right Size

Selecting the right aluminium angle sizes ensures:

- Performance: The correct section can support weight, resist distortion, and endure wear.

- Efficiency: Using the right size reduces material waste and fabrication time.

- Aesthetics: Different profiles suit modern, minimalist or industrial design schemes.

With aluminium’s natural resistance to corrosion and low maintenance requirements, the right angle size can deliver long-lasting results.

Custom Aluminium Angles

At Gooding Aluminium, we also provide custom aluminium angles tailored to specific project requirements. This includes:

- Bespoke lengths

- Specialist finishes (anodised or powder coated)

- Precision cutting for seamless installation

Our in-house team ensures that each order meets exact specifications, giving architects and fabricators confidence in every project.

Conclusion

Understanding aluminium angle sizes is essential for maximising both structural performance and design flexibility. From equal to unequal angles, the choice of profile can significantly impact the strength, aesthetics and efficiency of a project.

Explore the full range of aluminium angles available at Gooding Aluminium or contact our expert sales team for tailored advice.

Contact us today:

020 8692 2255

sales@goodingalum.com

Frequently Asked Questions (FAQs)

Q1: What is the difference between equal and unequal aluminium angles?

A1: Equal aluminium angles have legs of the same length, providing balanced strength. Unequal aluminium angles have one longer leg, offering greater flexibility for custom applications.

Q2: Can aluminium angles be used outdoors?

A2: Yes. With the right finish, such as anodising or powder coating, aluminium angles are highly resistant to corrosion and suitable for exterior use.

Q3: Are custom aluminium angle sizes available?

A3: Absolutely. Gooding Aluminium offers bespoke cutting, finishing and lengths to match specific project requirements.